Decoration Methods

Become an expert in branding solutions

Over the years we have established great partnerships with the best decorators in the business.

We offer a range of decoration methods depending on what is most suitable and durable for your product and its intended use. Take a look at our extensive list of decoration methods to discover which techniques will best represent your brand and budget.

EMBROIDERY

Everyone’s favourite decoration method for its simplicity and durability. Our decorators work with quality threads and over 1,000 heads of modern embroidery machines. Your logo will retain its quality appearance and long outlast the life of the garment itself.

How does embroidery work?

All embroidery jobs are produced based on a plot sheet. Plot sheets are created by reproducing your logo in a process called ‘digitising’. These plot sheets contain important information that tell the decorator which threads and colours to use as well as how to set up your logo at the correct size and amount of stitches.

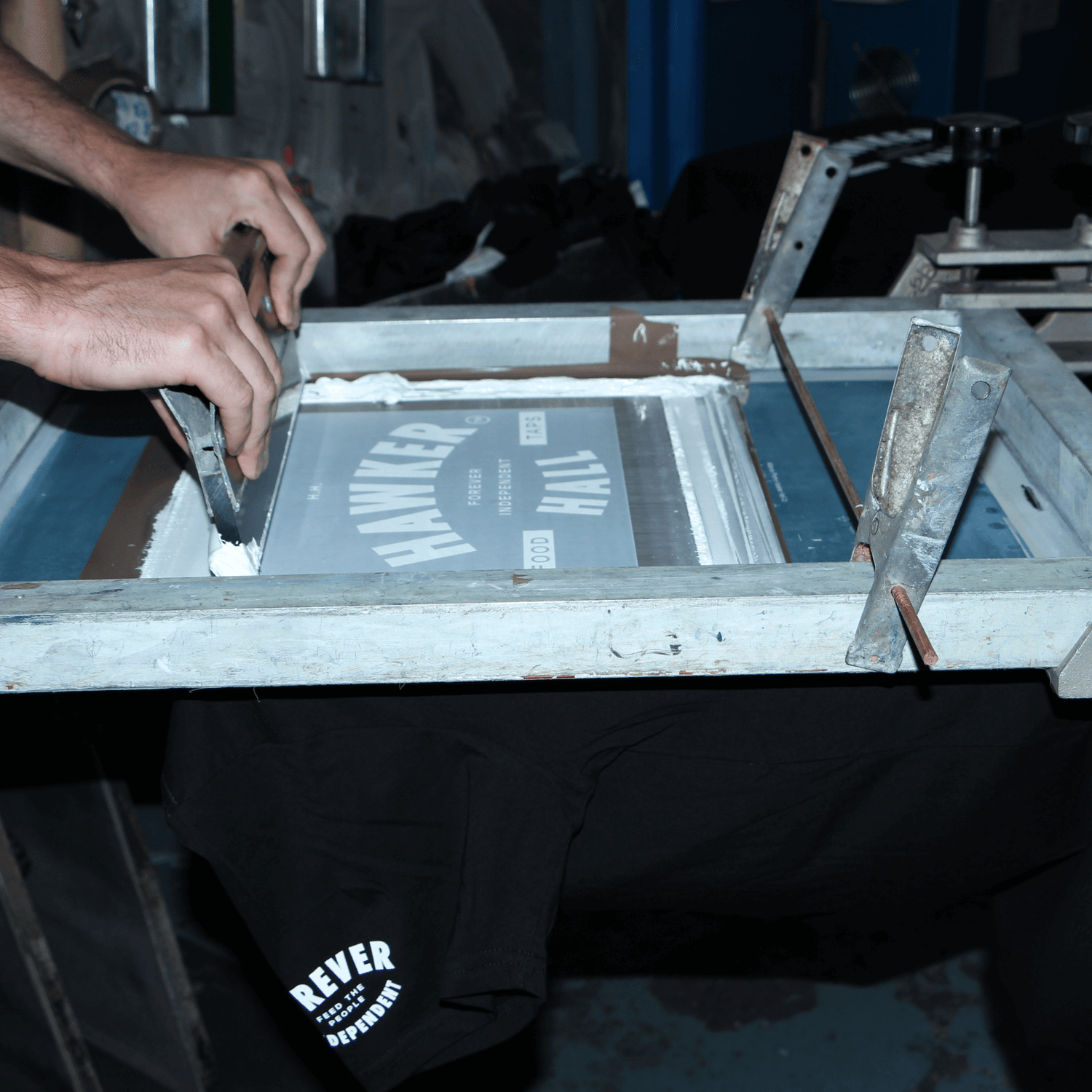

SCREEN PRINTING

Screen printing provides a sharp and consistent print with strong and vibrant colours that can be applied to a wide range of garments and materials.

How does screen printing work?

Before we can print your logo we need to create a screen. This screen acts as a stencil of your logo and is then placed over the garment. Ink is then spread over the screen. Your logo must be separated into solid colours as each colour requires a different screen. Screen printing can be done manually for smaller orders or on automatic machines for larger orders. The garment is then fed through a heater to dry.

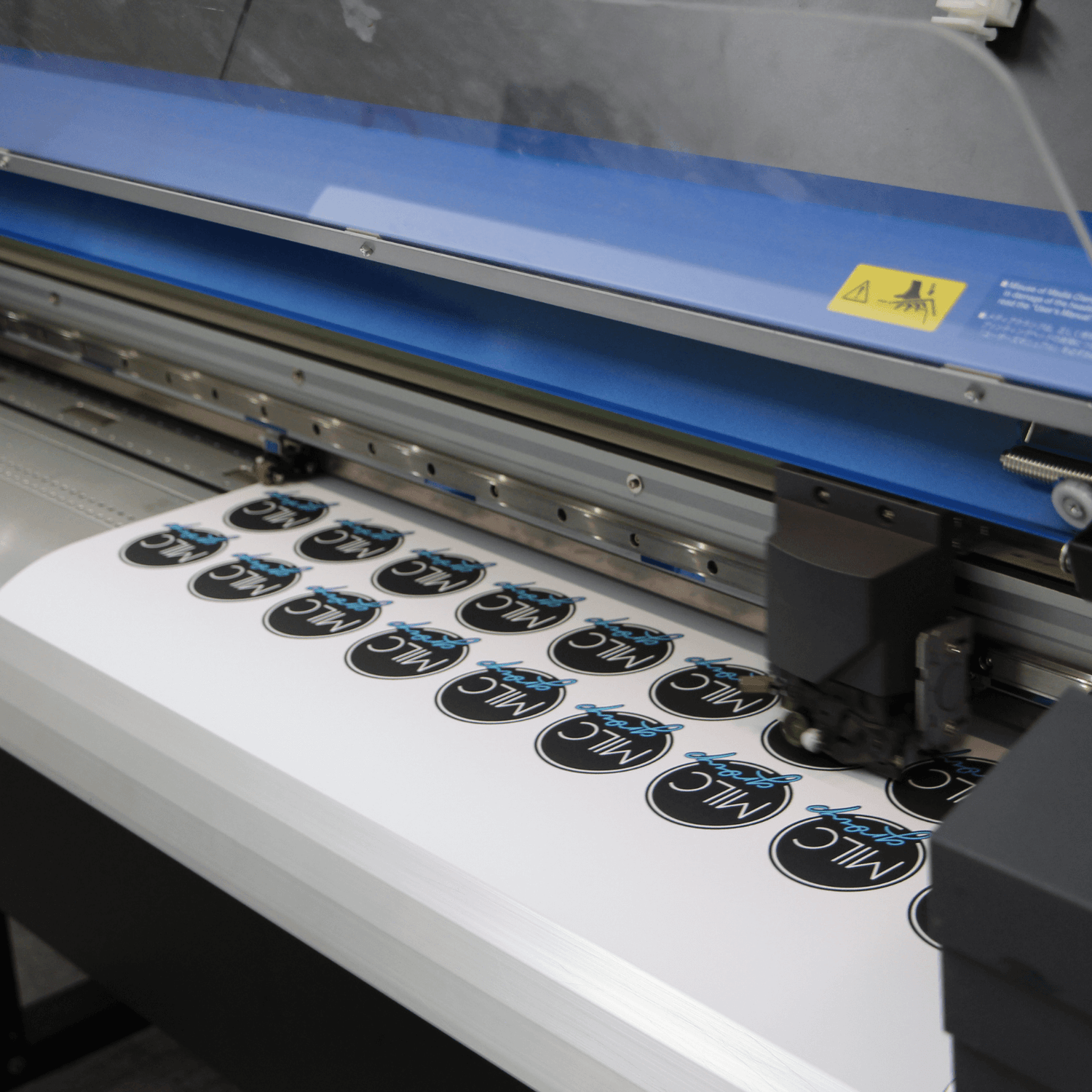

TRANSFERS

Digital, plastisol and any other heat applied transfers are designed for fast and easy application to a large range of textiles.

How do transfers work?

Transfers produce vivid colours, crisp lines and detailed logos that have gradients and multiple colours. Transfers are printed using specialised machinery, weeded to remove any negative space between letters or shapes and then applied directly to the garment by using a heat press to bond the transfer to the material.

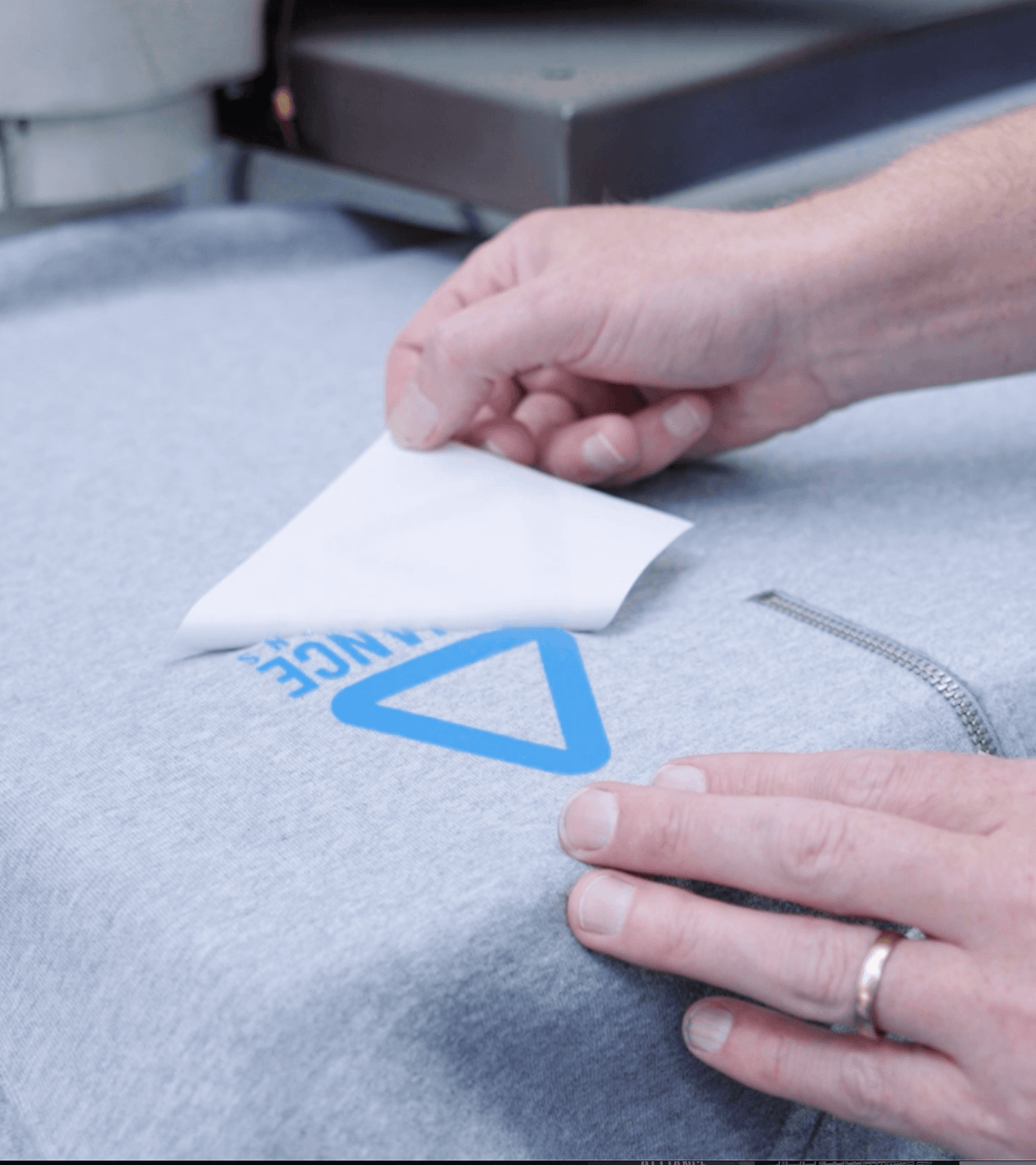

SUPACOLOUR

Supercolour is a revolutionary new way of decorating a range of promotional products and apparel.

How does Supacolour work?

Supacolour is based on the traditional process of transfers but delivers far superior results in terms of colour vibrancy, smooth gradients and sharp photographic content. Supacolour allows for fine detail and small text which are usually set up as block images without the need for weeding.

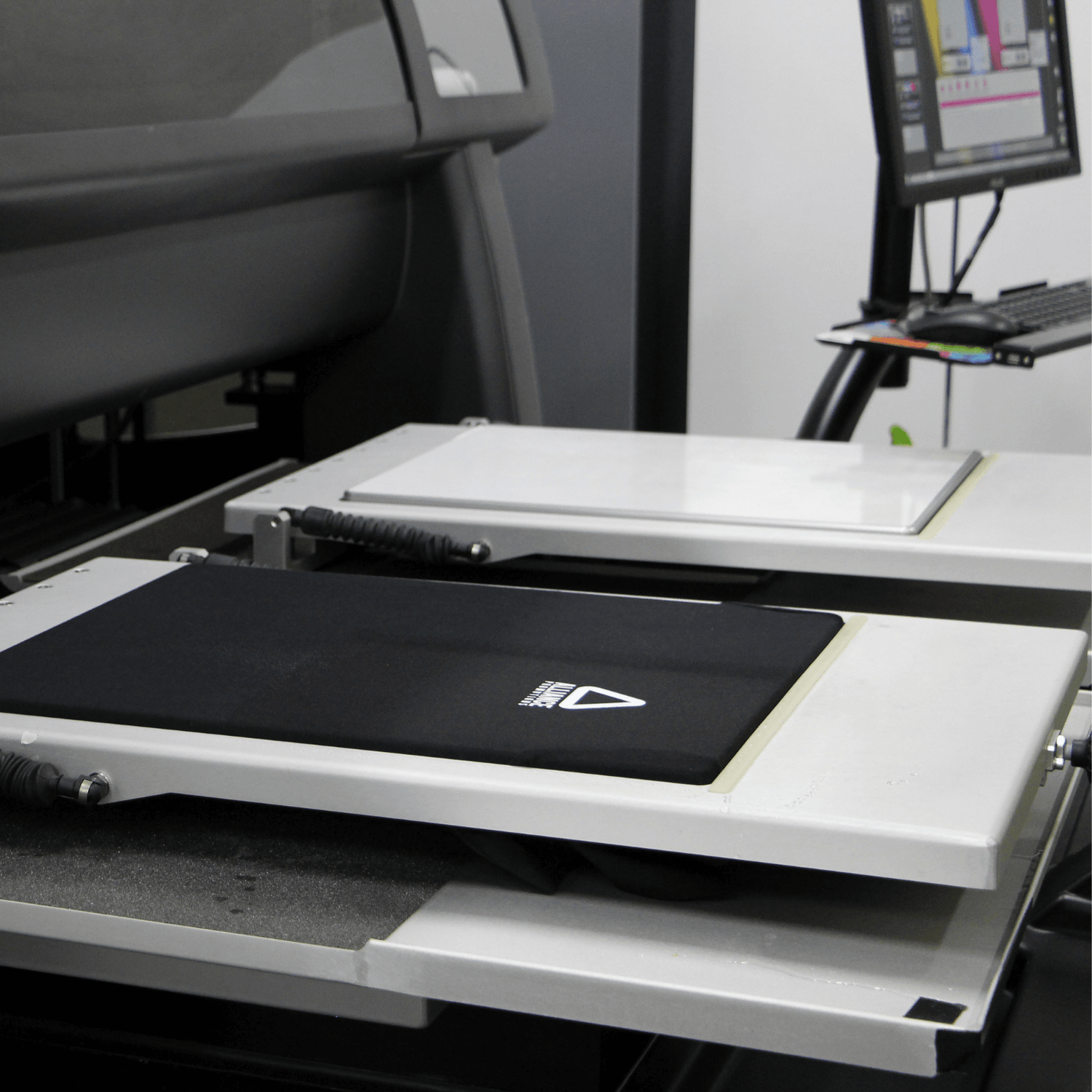

DIRECT TO GARMENT PRINT

Direct to garment prints provide a durable and long lasting decoration perfect for any size order.

How does direct to garment printing work?

Your logo is set up so that it is readable by the printer and a few tests are printed on a clear plastic sheet to ensure perfect positioning. Garments are then placed on specialized equipment tightly held together with a clamp so there are no creases. The garment is then sprayed with a solution which is collected by the material. The printer then prints directly onto the garment just like a standard printer would and fed through a heater to dry.

SUBLIMATION

Sublimation is a full colour and full coverage printing technique where special dyes are transferred onto polyester fabric.

How does sublimation work?

Sublimation dyes are printed in reverse (face down) onto large sheets of paper using offset screen or digital printing machines and then heat pressed onto fabric (usually white or light coloured). During the sublimation process, solid dye particles convert into a gas where they diffuse into the polyester fibers and re-solidify.

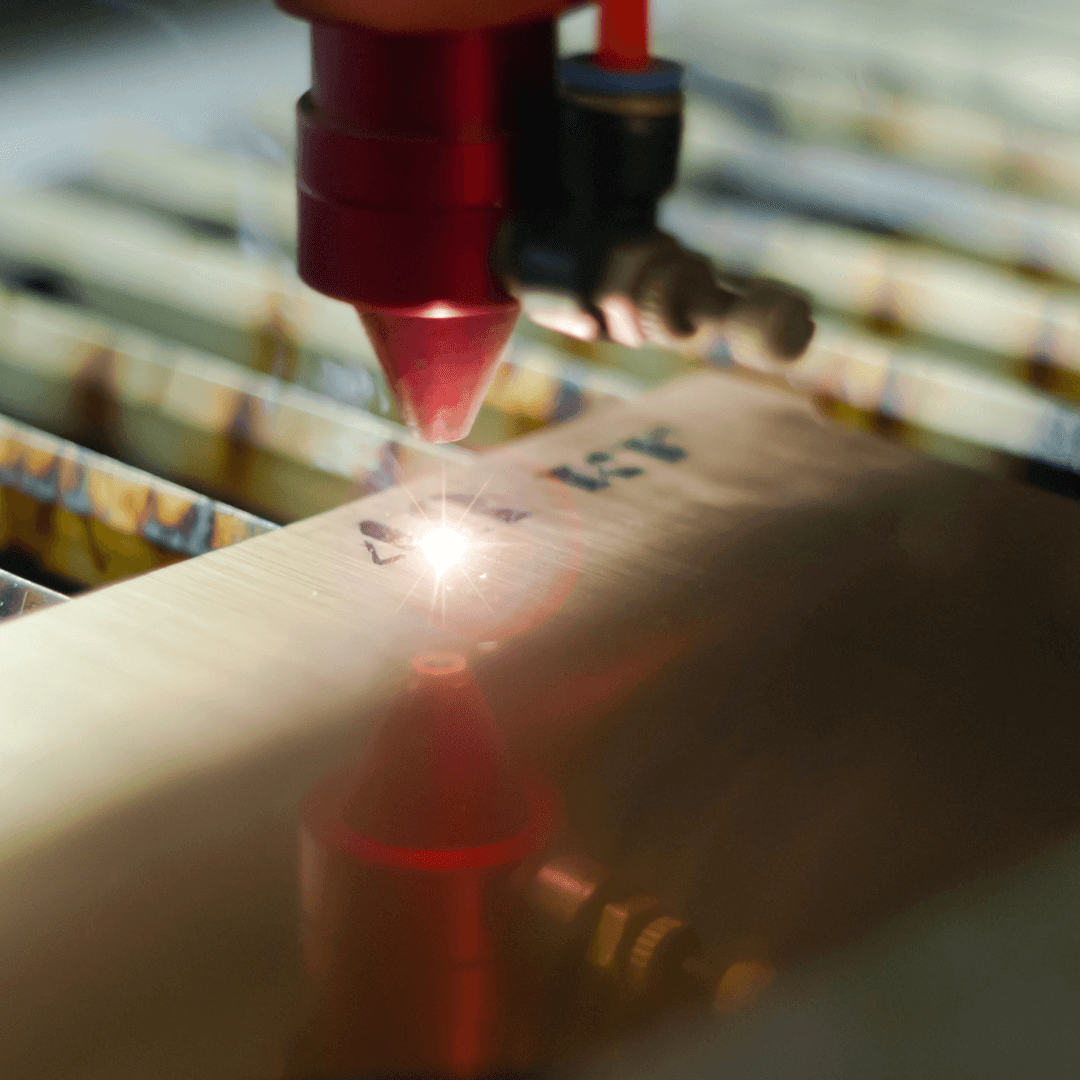

LASER ENGRAVE

Laser Engraving is the practice of using lasers to engrave or mark an object. The technique does not involve tool bits which contact the engraving surface and wear out.

How does laser engraving work?

Your logo is set up on the machine to ensure fine details are captured and correct positioning is achieved. Lasers then burn the substrate to achieve a permanent and detailed design.

PAD PRINTING

Pad printing allows us to decorate otherwise impossible products by transferring a 2D image onto a 3D product.

How does pad printing work?

A plate is created that holds the etched image that needs to be printed. This etched image is filled with ink and then using an indirect offset printing process the image or logo is transferred via a silicone pad directly onto the substrate.

Get in touch today to discuss the best decoration methods for your next project.